CondorTM Platform

Intelligence for production

Looking for advanced real-time factory control and analysis to optimise your plant and improve production output? Struggling with complicated paper trails or an obsolete process control system? Our manufacturing execution system offers a solution.

Our Condor platform is a low-cost manufacturing execution system with built-in open interfaces to a wide variety of common and bespoke SCADA, PLC and ERP systems.

Some highlights of our Condor Platform

Our magic integrates all the systems you use

ERP Integrations

We built our MES to play nicely with others because we believe data should flow freely throughout your factory. We've built integrations with Adifo, SAP, Palladium, and Sage to name a few. Tell us about what integrations you'd need and we'll find a way to get it working. Problem solving is at the core of what we do at Promtek.

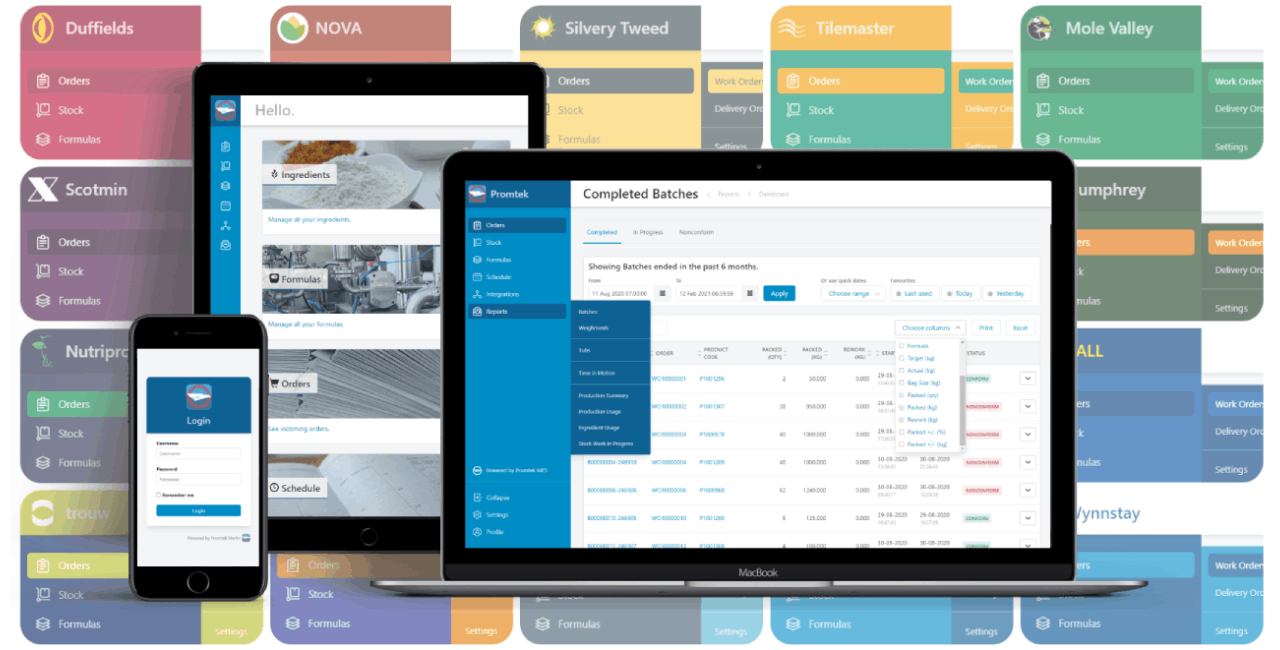

Themed to fit your company

We've developed our MES to visually integrate with your branding. It looks great and we know that you'll love using it. Whether you're in the office on a computer, on the factory floor with a tablet, or in the pub with your phone; our MES works flawlessly across all of your devices.

Scheduling and contamination

Our scheduling system contains all the smarts to send the neccessary orders down to your control system. With an intuitive drag-and-drop interface, we've made it simple to schedule orders across multiple production lines. Our contamination algorithms ensure that you catch any issues before your schedule gets sent to you control system.

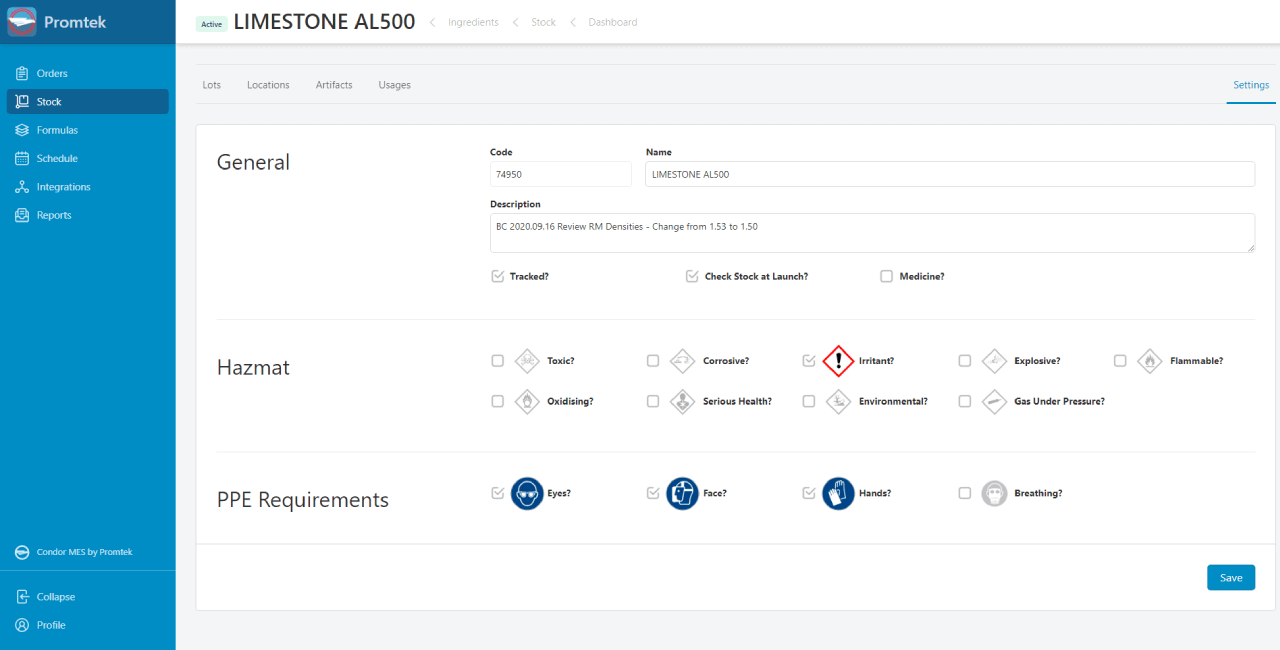

Stock traceability

Tracking and tracing is important in all aspects of life, but especially in your factory. Our MES controls and tracks all the stock batch numbers and locations. Anything moved within your control systems will be synced to the MES and will generate artifacts and notify financial systems of changes.

Beautiful batch reports

All files that the MES receives from all your integrations generates artifacts with a full history of stock received, weighments that have been done, and orders that have been completed. These are then synced with your financial systems to ensure the MES and your ERP are singing from the same hymn sheet.

Testimonials

A few words from some of our beloved customers

"Promtek are a valued partner and possess a very capable System Integration team. Promtek have been able to support us in a wide range of projects, from obsolescence to large scale plant automation and always deliver in terms of quality."

Simpsons Malt

Berwick-Upon-Tweed

"We have been a long standing Promtek customer and have recently completed a large expansion programme which included upgrading the Promtek system. The new HD Graphics package along with the MES system has transformed to process control of the mill. The staff at Promtek are great to deal with from the customer service team through to the software developers they really are customer focused and make a point of getting to know our business."

Wes Larner

Duffields, Yeovil

"Promtek are very versatile both site mechanical and control system wise. We've seen an increase in daily tonnage from an average of 700t per day to 850t per day, with a record day of 944 tonnes. Promtek stands out because of the overall quality of their graphical display and the amount of information accessible on batch data reports. We have a very good working relationship with Promtek and their staff are friendly and efficient. Any problems are quickly sorted."

Ray Jones & Jamie Davies

Wynnstay, Powys

Contact Promtek

If your enquiry is urgent or requires technical support, please have your support contract number to hand.

Fisher Street

Stoke-on-Trent, Staffordshire

ST8 7QJ

01782 375600

sales@promtek.com

We'll only use your details to contact you about this.